Sustainable Glove Solutions

Please note: Since our initial publication in May 2024, the ASTM D5526‑18 standard was officially withdrawn on July 7, 2025, with no replacement. ASTM’s ballot concluded that “there is no correlation between this test and actual landfill biodegradability.” Guidance for the use of the other biodegradable standard for nitrile gloves, ASTM D5511‑18, is also under review due to its limited real-world application. We will update the biodegradable glove information claim as soon as the review is finalised.

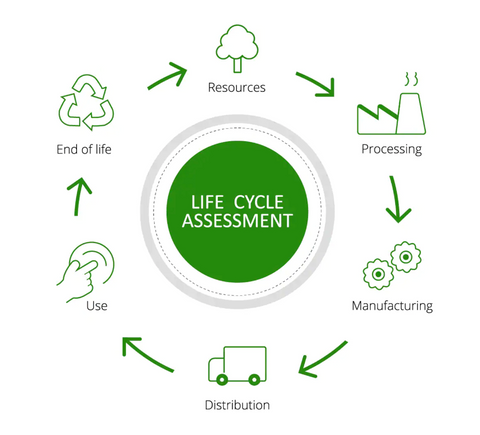

Are biodegradable gloves the only sustainable glove option? Research suggests reviewing the full life cycle of a glove, impacting stakeholders and the environment, not only at the end of life (disposal).

Biodegradable Gloves: Are They the Answer?

Nitrile gloves are made from the polymer nitrile butadiene rubber (NBR), a fossil-based polymer. Some glove manufacturers claim that the addition of specific additives will cause accelerated biodegradation of nitrile gloves. However, there is no scientific evidence to support that an additive can change the molecular structure of nitrile and allow it to biodegrade. In reality, accelerated degradation occurs, which may result in the creation of microplastics that are harmful to humans and the environment.

While the sources and data used to support nitrile glove biodegradability claims may look legitimate, they can be misleading. It is reported that claiming “biodegradability” without indicating the environment in which the biodegradation takes place is increasingly perceived as greenwashing and should not be used. Learn more about other glove materials here.

"No scientific evidence substantiates the claim that an additive can alter the molecular composition of nitrile, enabling biodegradation."

Standards Relating to Plastic Biodegradability

The applicable standards relating to plastic biodegradability (and applicable to nitrile) both measure degradation over a specific time; neither test can be used to predict future biodegradation. These tests do not provide pass/fail qualifications; therefore, a product can be tested against these standards, but it does not result in a certification or proven biodegradability.

-

ASTM D5526-18 - Measures Biodegradation of Materials in Landfill Scenarios*

*This standard has been officially withdrawn with no replacement because THERE IS NO CORRELATION BETWEEN THIS TEST AND ACTUAL LANDFILL BIODEGRADABILITY.

Limitations: Because a wide variation exists in the construction and operation of landfills, and because regulatory requirements for landfills vary greatly, this procedure is not intended to simulate the environment of all landfills. However, it is expected to closely resemble a biologically active landfill's environment. More specifically, the procedure is intended to create a standard laboratory environment that permits rapid and reproducible determination of the anaerobic biodegradability under accelerated landfill conditions, while at the same time producing reproducible mixtures of fully and partially decomposed household waste with plastic materials for ecotoxicological assessment.

-

ASTM D5511-18 - Measures Laboratory Conditions*

*This standard is currently under review to strengthen guidelines on biodegradable claims. Current guidance for the use of this standard states: “Claims of performance shall be limited to the numerical result obtained in the test and not be used for unqualified ‘biodegradable’ claims".

Limitations: As there is a wide variation in the construction and operation of anaerobic digestion systems and regulatory requirements for composting systems vary, this procedure is not intended to simulate the environment of any particular high-solids anaerobic digestion system. However, it is expected to resemble the environment of a high-solids anaerobic digestion process operated under optimum conditions.

Additionally, landfill specialists caution against over-reliance on biodegradability claims, emphasising the importance of material breakdown into digestible components rather than simply fragmenting into smaller pieces.

“The Biodegradable and Compostable standards are based on tests that rate the material’s ability to break down (biologically) into pieces small enough so a certain portion will pass a certain sized mesh after a certain time. They do not place much value (if any) on the material itself for any subsequent purpose/state (e.g., composting or energy recovery). The fact that it can break down into smaller pieces does not determine whether the material is actually adding any value—it just means you can’t see it anymore.

In our opinion, there is no value to the landfill or the environment for a “biodegradable” nitrile glove to be in one piece or 10,000 pieces. “It may not choke a turtle, but it will still choke an earthworm” is the common phrase used to create an understanding that even if it is so small you can’t see it, it doesn’t mean it isn’t there. The only value is for any material to break down into pieces that are in themselves small enough to be digested by bacteria as food. Also, that the molecules that make up the material are short carbon cycle (not synthetic / fossil-fuel based, but rather grown within the biosphere).”

- Tyron Hartle (Lead Sustainability Partner), and Tim Brake (Landfill Specialist) from WM New Zealand

Sustainable Glove Solutions: Full Lifecycle

- Glove raw material quality is directly responsible for glove durability and performance. Conversely, gloves will rip and tear if manufactured using cheap, poor-quality materials, increasing waste. Consideration must be given to gloves made from better quality materials to reduce usage. Third-party supplier certifications to verify quality are recommended.

- Cheap and toxic glove raw materials can cause glove-wearer skin irritation and affect long-term health. Choose gloves without accelerators and with known skin benefits.

Processing & Manufacturing:

Ansell’s life cycle assessment highlights responsible manufacturing as having the greatest environmental impact, using processes that conserve resources and reduce pollution. The assessment found that approximately 64% of carbon emissions came from production.

- Factories with renewable energy sources and water recycling and conservation systems will reduce greenhouse gas emissions.

- Purchasing from manufacturers with zero waste targets with recycled packaging options helps reduce emissions and waste.

- Consider independent environmental and quality assurance factory audits.

Distribution:

Sourcing higher-performing lightweight gloves with greater durability means more gloves per carton and container, reducing international and national CO2 transport and distribution emissions.

Usage & End of Life Waste Reduction:

- Thickness: Commonly, glove thickness can be reduced with better quality gloves, reducing your waste stream.

- Harmful Toxins & Chemicals: These can cause long-term skin issues for wearers, as well as contributing to land and wastewater contamination. Vinyl gloves can be particularly toxic with BPA, PFAS and dioxin, as well as vinyl chloride emissions during manufacture and disposal. Review glove type and trial glove quality before purchasing.

- Waste: Reduction is possible as more durable gloves have a lower failure rate.

- Reducing glove failures (ripping) and usage will directly reduce the amount of waste sent to landfills.

Nitrile gloves deemed ‘biodegradable’ typically cost more, and as the evidence suggests, could be hard to justify given the unproven benefits. We encourage you to consider the full glove lifecycle when selecting a sustainable glove option, including responsibly sourced nitrile gloves with proven performance, no harmful toxins and an overall reduction in glove usage and waste.

Information has been sourced from the following regulatory standards and industry experts: